Ourglass is kind of a big deal to me. It’s my baby. It’s the reason I learned to solder SMT properly, in an oven, with the right temperature curves and everything. It made me learn to use 3d printers and KiCad and got me several conference talks. It has its own twitter. After about three years, I’ve put the project aside, but I still catch myself thinking thoughts about a better smart watch.

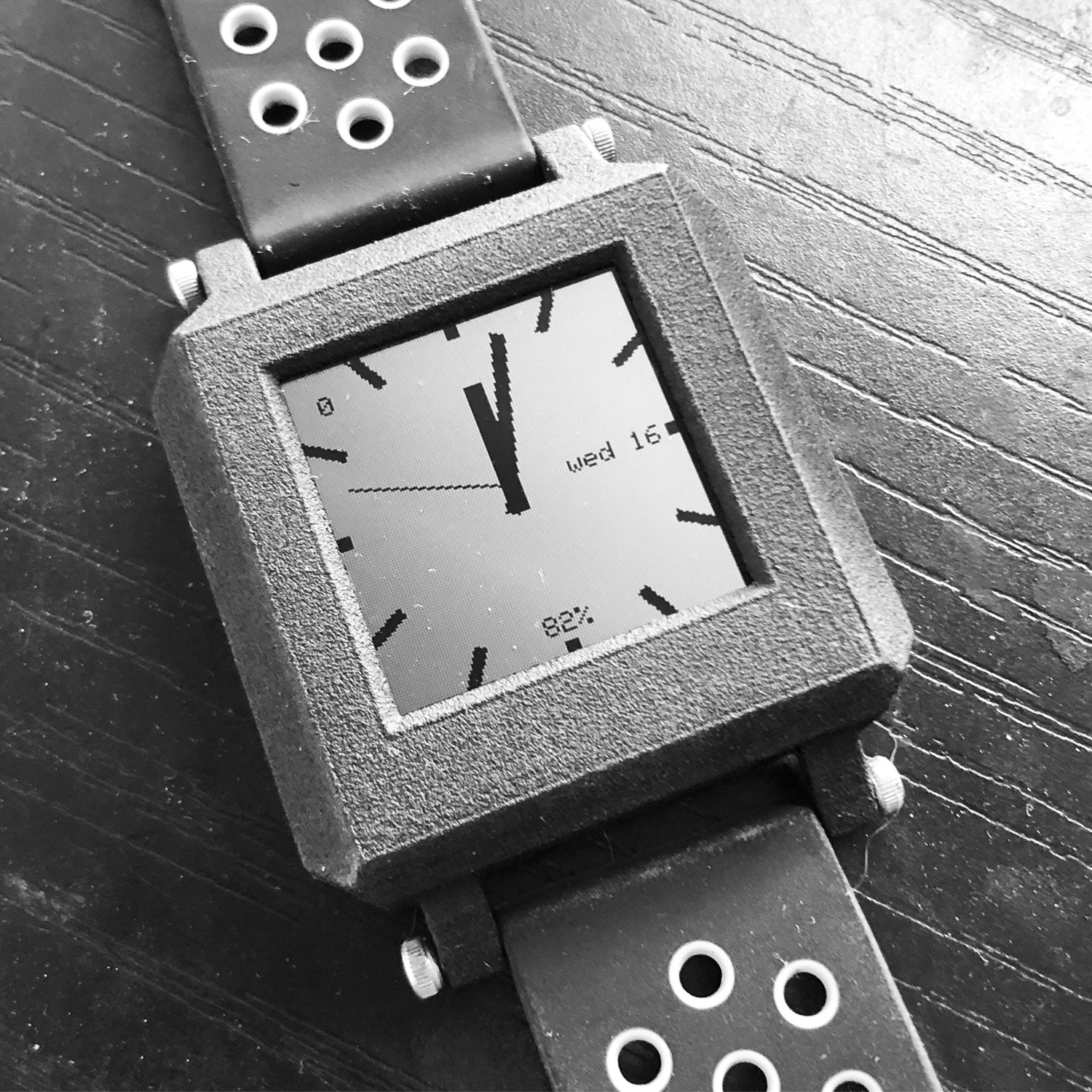

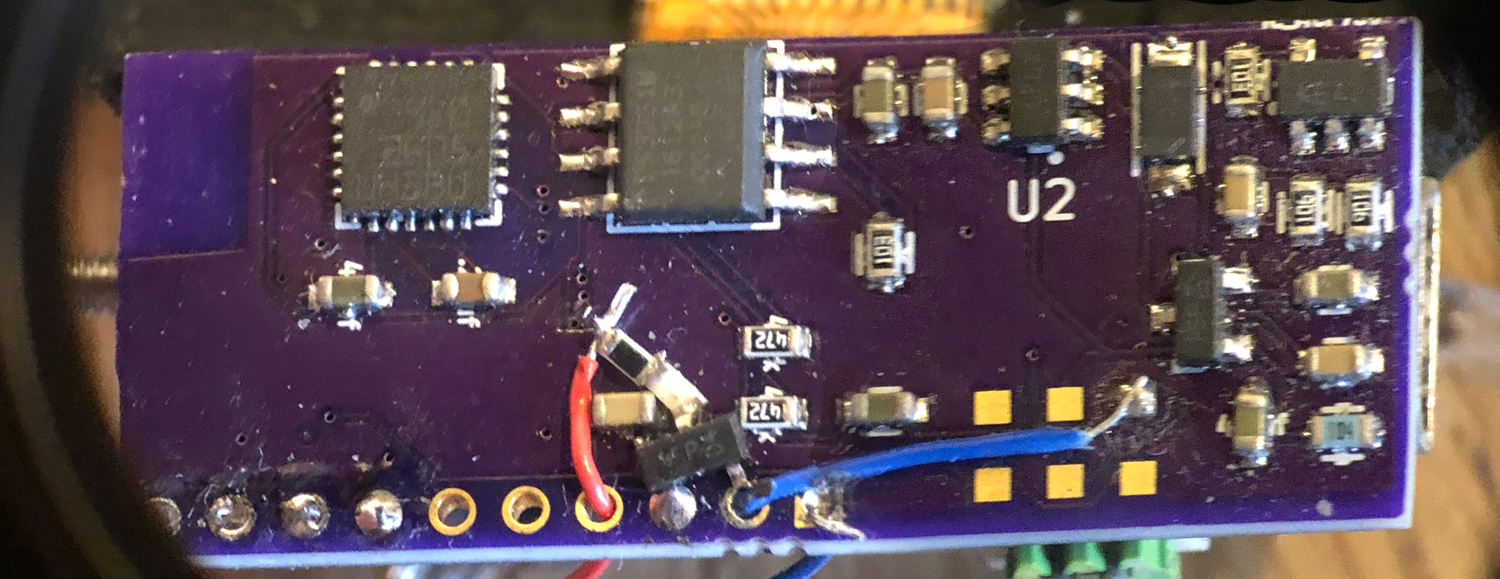

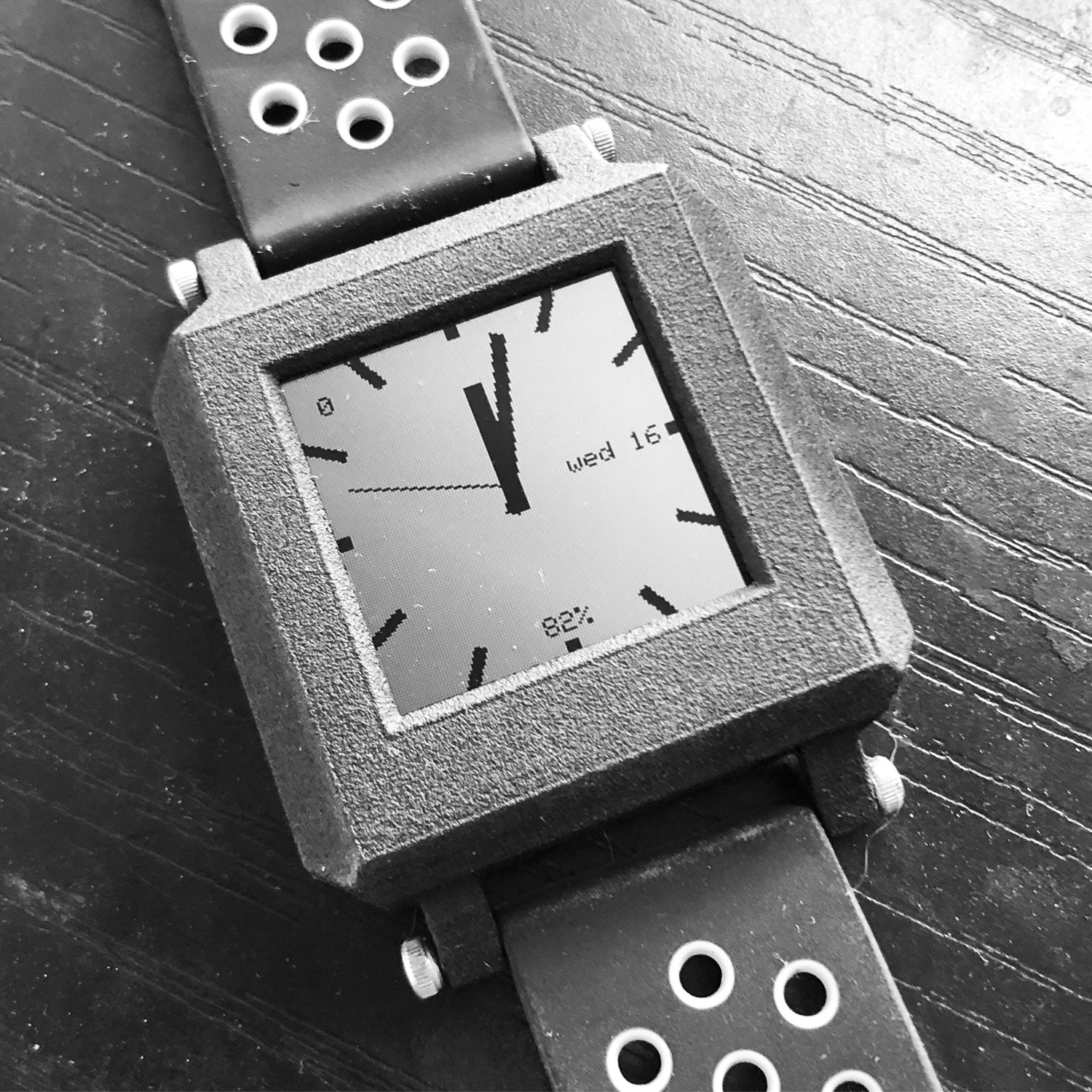

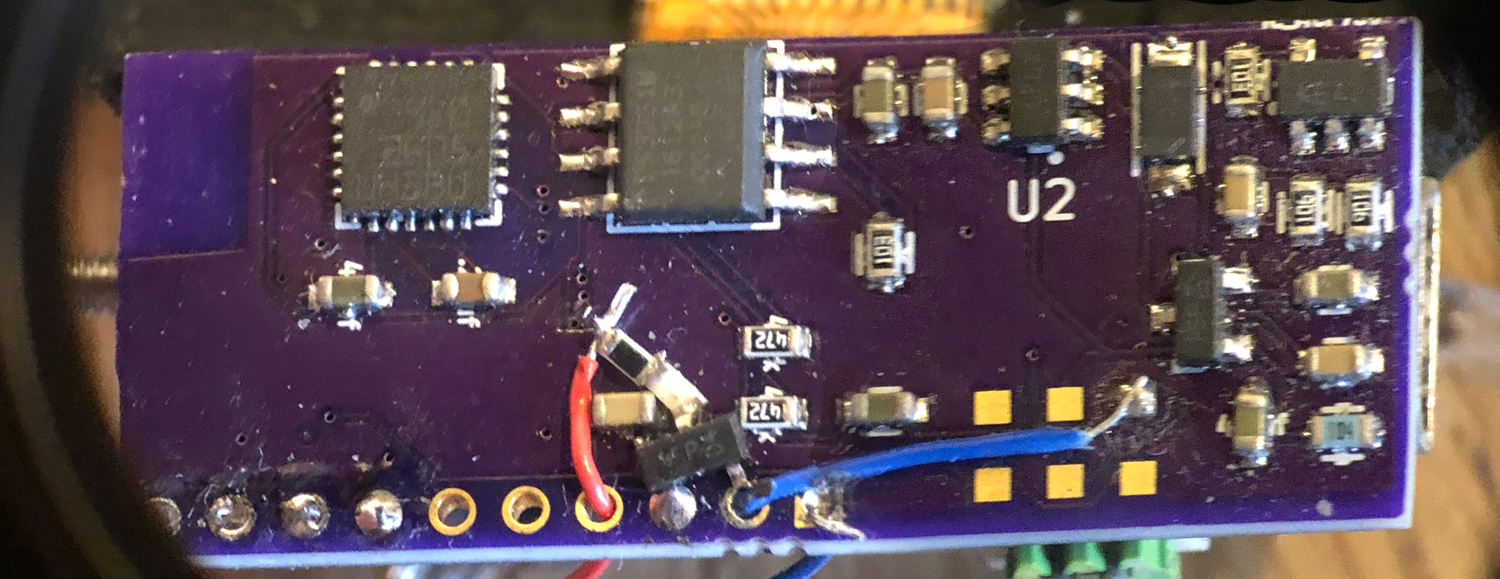

These photos are of the final version 7 as assembled, with a vibe motor for notifications, and the buttons blocked off. The watch also features a bluetooth connection to any BLE-compatible smartphone, an accelerometer for step counting, a real-time clock for accurate timekeeping, an always-on screen, and a 3-4 day battery life. I made versions that were half the thickness of the apple watch, just to show off.

The original reason for doing this was to take some of the control of my personal data back from bigcorps, and then later because smartwatches that were available simply were bad for telling time. The choices I made were deliberate; I could have had a color screen, but then battery life would suck and it wouldn’t be readable in bright sun. I could have added a lot more features, but instead I made the expansion header, to allow myself more flexibility.

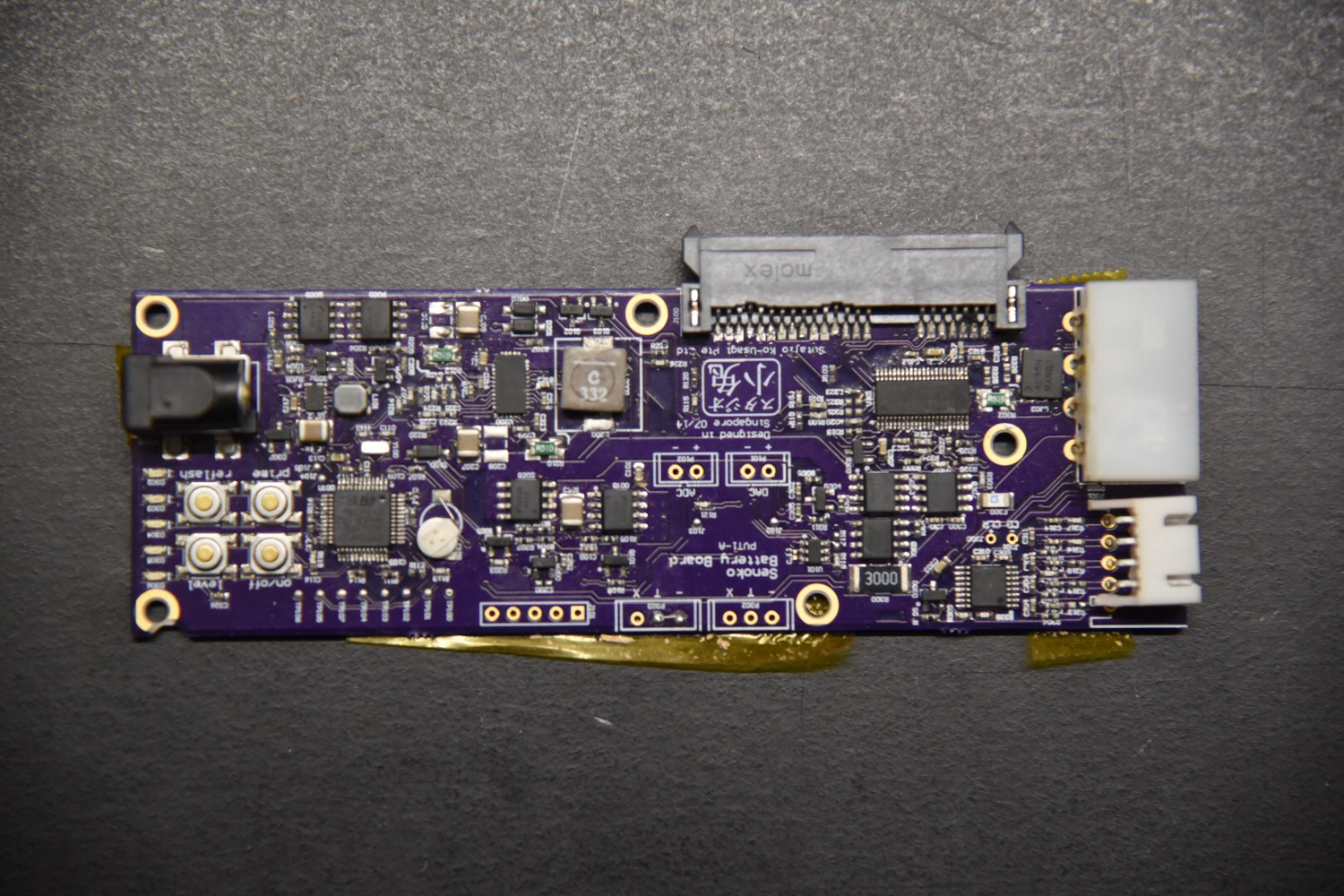

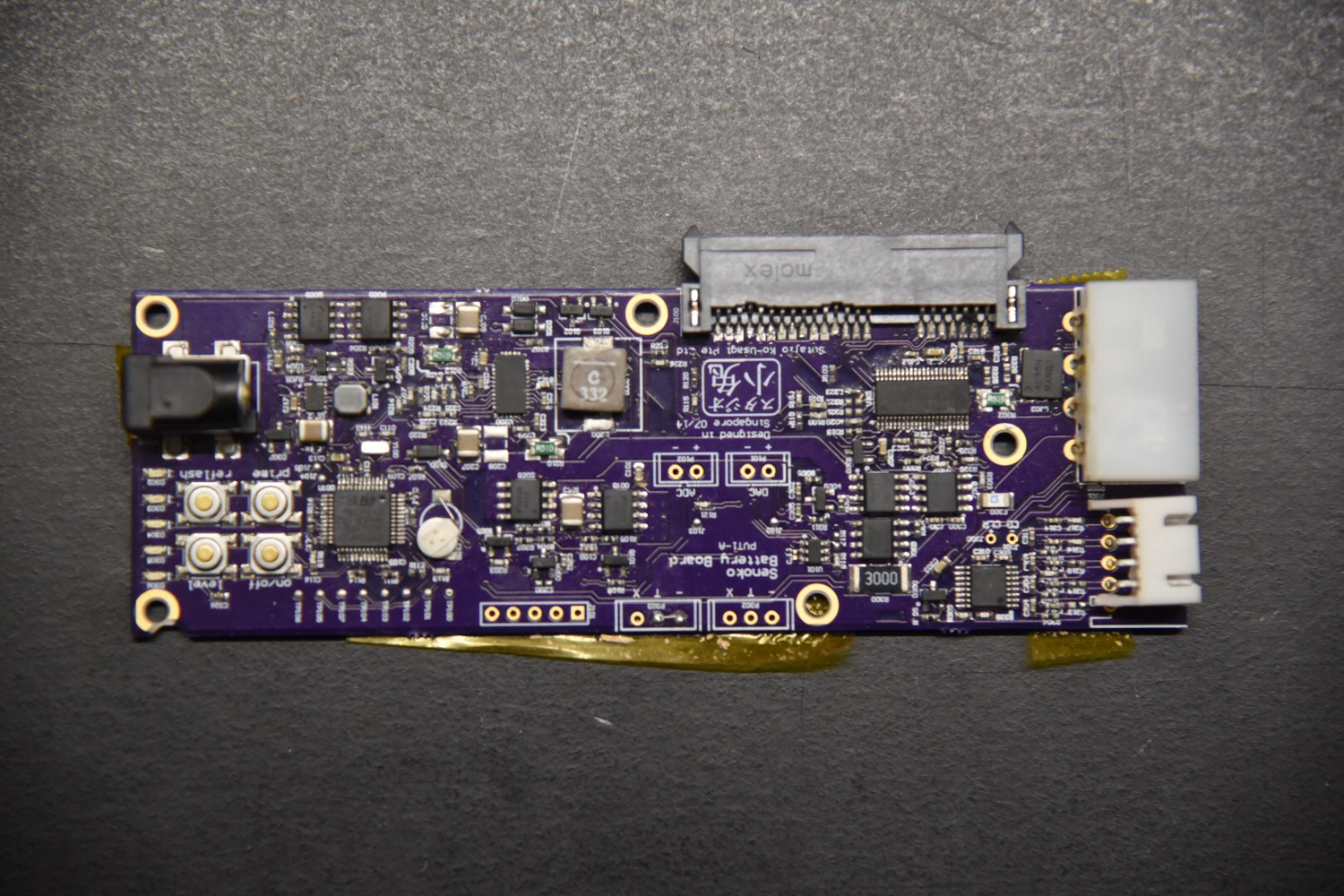

This was a part of a laptop I built when I decided I needed something I could repair. I bought a Novena bare board and worked from there to build a laptop. This was a major component, which allowed the use of RC batteries to power the board. The design came from the Novena people (Bunnie and Xobs), but this was probably the most complex PCBA I’ve ever put together. Passives as small as 0201, ~200 hand-placed components.

This project started out with me thinking I needed to buy a mill and put it in my 12x8 shop space. I decided, though, that the first thing a shop really needs is a welder, because a lot of time setting up a shop is spent making furniture and stuff, and a welder is super important. So I picked up a little Miller Maxstar that will run on 110 (it gets more amperage on 220 but I don’t really need it). Then I went to buy steel to make the table for the mill, and found out that I could only buy whole plates of quarter inch sheet metal. So one desk became two.

I still haven’t bought the mill, but the welder found a nice home on the smaller table, and when the Hayward Fault goes, I can dive under the big table. I’m fairly sure it’ll hold the house up away from me. All the support structure is 2” box tube, with 1/8th” walls. The big table has castors that touch the ground when the leveling feet are screwed all the way up, to make moving it easier (photo 2 shows the bracket for the castor).

There's no such thing as too much shop organization. The stuff I have out tends to expand to fill the available surfaces, and the solution is to make the tools as easy to put away as possible, while also keeping them close enough to use at a moment's notice. This is my solution: a bunch of 1" and 2" square tubes, welded together, to hold tools upright and just at the back of the bench.

This may have just been a little side-project to try to bring some order to the welding bench, but it also was doing double duty. I didn't need to weld out the entire length of the tubes, but I did need to practice TIG techniques before completing the bicycle frame I'm working on, and the best way to learn is to burn some rods.